Phone: +49 7142 938-0 | E-Mail: info@geiger.de

Phone: +49 7142 938-0 | E-Mail: info@geiger.de

The § 33 Musterbauverordnung (MBO) - German standard building regulations - requires the exis- tence, for each floor, of at least two independent emergency exits.

One of them must comply with the regulations defining the first emergency exit. The first emergency exit enables people to quickly leave a danger zone. It leads either directly into the open air or into a secured area, such as corridors, stairs and exits.

Unlike the first emergency exit that is strictly regulated and clearly defined, the second emergency exit can be interpreted in different ways and faces countless solutions. Until now, uniform regulations have not been applied throughout the country.

For sun protection manufacturers, architects and planners, this represents a huge challenge in terms of design and implementation and might lead to conflicts.

Especially if the fire safety requirements for the second emergency exit are not respected. Further- more, aesthetic aspects, historic preservation regu- lations, constructive environment and, last but not least, costs have to be reconciled in a constructive dialogue.

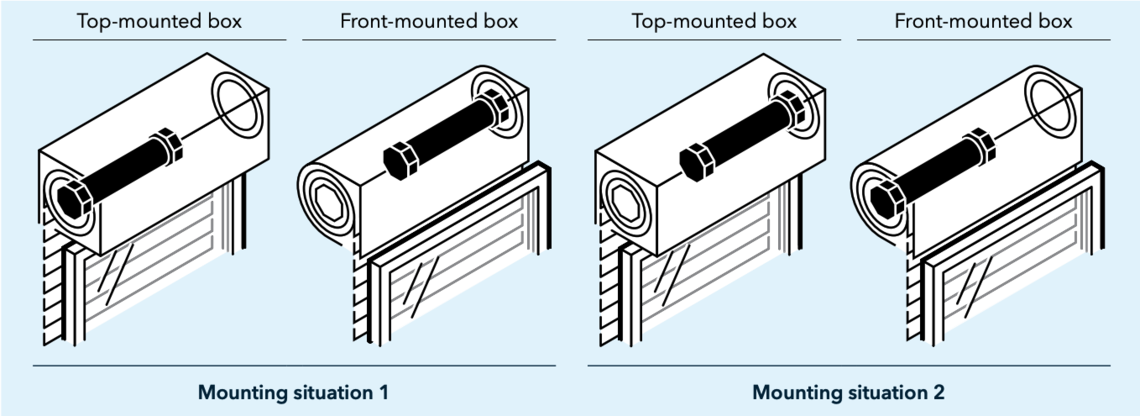

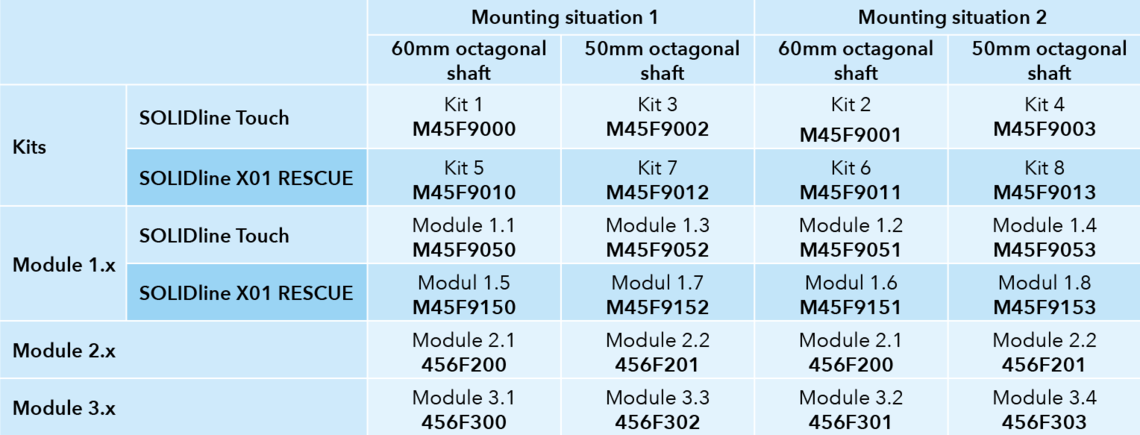

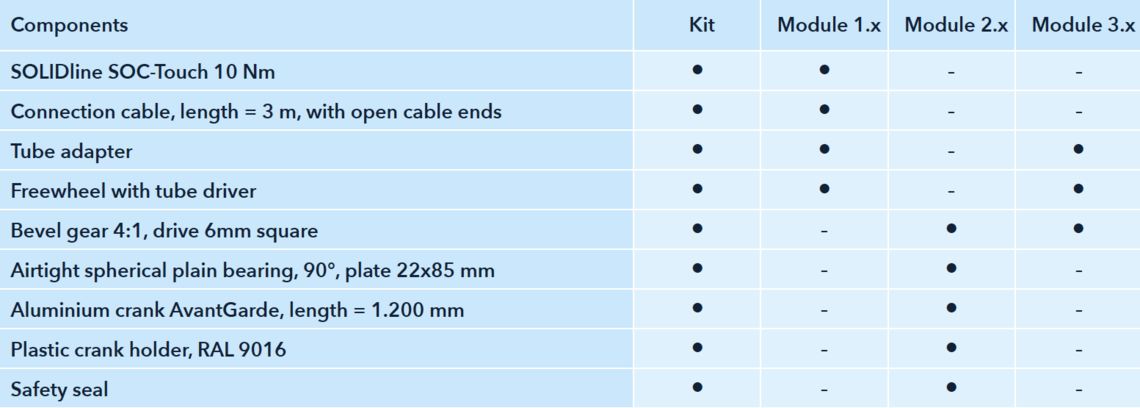

The sophisticated design of the RESCUE-R can be easily integrated into all standard roller shutters head rails. All components are dimensionally designed in such a way that only the crank handle has to be installed inside the building.

If the roller shutter cannot be raised electrically in the event of a fire, RESCUE-R comes into operation. Simply pull the crank out of the holder, push the sleeve of the AvantGarde crank upwards and bend and turn the crank. The safety seal serves as a visual indication that the crank should only be operated in an emergency.

No measures are necessary when restarting the SOLIDline Touch. If the shutter has been opened with the crank, the crank should be turned a quarter of a turn in the opposite direction before being put back into operation in order to relieve the gear and prevent the crank from turning during motor operation.

The freewheel with shaft driver is fitted to the motor. The system is installed as usual, except that the gearbox is fitted instead of the counter bearing and the roller capsule. If a certain direction of crank rotation is desired, the gearbox can be rotated axially by 180°. The shaft length/curtain width must not be less than 750mm.

|